Instrument maintenance

Instrument maintenance

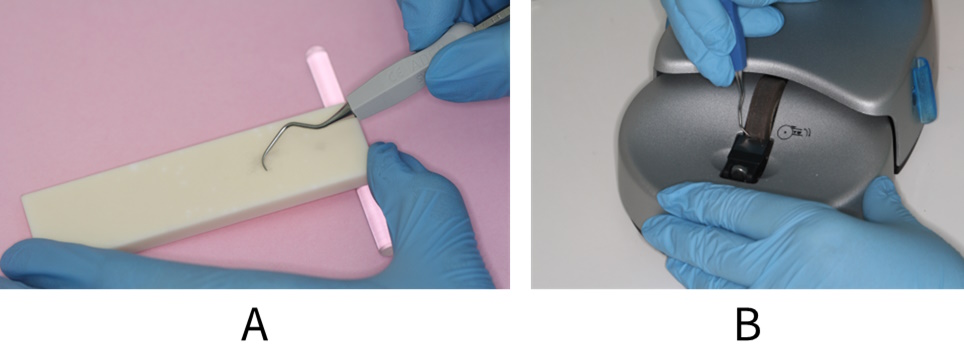

The effective removal of calculus using hand instruments results in a dulling of the cutting edge of the blade. Studies have shown that this can result in a less effective cutting edge after relatively few strokes. Hand instruments, therefore, require meticulous maintenance to ensure they remain fit for purpose (see figure: Instrument sharpening). Sharpening of such instruments requires both skill and knowledge of the design characteristics of each type of instrument. Instruments can only be sharpened a finite number of times before they must be replaced due to the risk of fracture of the blade.

Image A shows sharpening of a hand instrument using a sharpening stone. Image B shows sharpening of a hand instrument using a powered instrument sharpener.

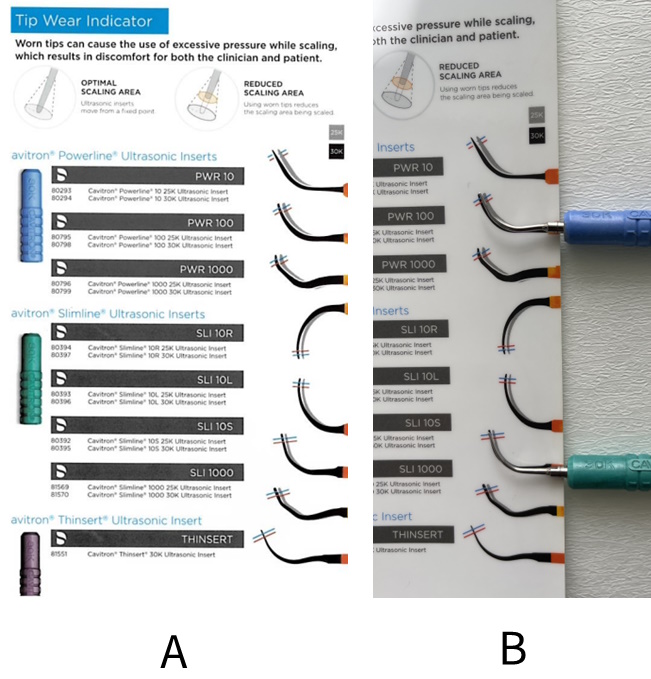

Powered scalers also require frequent inspection to ensure optimum performance. The tips of powered instruments wear with use and should be checked regularly, for example it is estimated that approximately 2 mm of wear equates to around a 50% loss of performance.75 Manufacturers provide information and guides to allow the clinical team to measure when a powered tip should be discarded (see figure: Checking ultrasonic tips).

A: Manufacturers’ guides are provided within the packaging of each new tip and should be retained for regular instrument checks. B: Ultrasonic tips being checked for wear against the manufacturer-supplied guide.

Keep hand instruments sharp and discard those which have reached the end of their useful life.

Regularly inspect sonic and ultrasonic instruments for signs of wear or distortion.

Follow the manufacturer’s instructions for checking, maintenance and cleaning of sonic and ultrasonic instruments.